Difference Between ANSI And EN388

There are two major global standards used to evaluate the protection levels of work gloves: ANSI/ISEA 105 (U.S. Standard) and EN 388 (EU Standard). It should be noted that EN 388 is also commonly cited in other parts of the world such as Canada, AUS/NZ and South America.The protection provides an amount of confidence to the industrial workers to work more efficiently and without anxiety and fear issues.

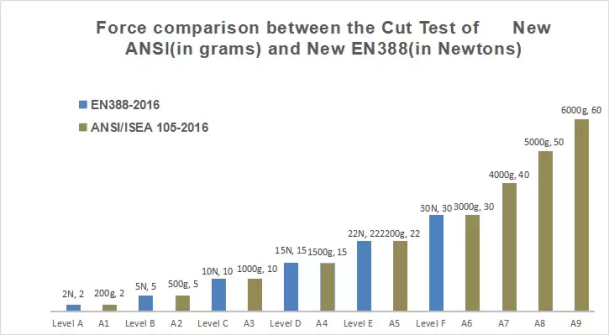

EN 388: 2016 will continue with the Coupe Test method and introduce the TDM machine for high-cut gloves testing beyond Level 3. EN 388: 2016 now incorporates ISO 13997 cut ratings A-F for high-cut fabrics.EN 388 terminology is used to describe the European cut resistance standards. The COUP method which includes moving a circular blade back and forth through the material and concluding the test results. The resistance test are equally done for abrasions, cuts and even the puncture resistance.

ANSI/ISEA 105: 2016 will increase the number of cut levels from 1-5 under ASTM F-1790 to A1-A9 under ASTM F2992 to provide more accurate and defined cut ratings. This allows ANSI to extend the old level 5 standard (1500g-3499g) and offer more accurate cut-resistant glove options beyond level 5.ANSI includes a testing method of passing a sharp blade into 20–25 mm of the glove surface. It is an American cut protection terminology.

Diagrams for

Therefore, it is difficult to make comparisons with each of these test methods and results (scores).

Note of TECHNICAL CHANGES:

1.Moving forward, ANSI/ISEA 105-2016 will use only the TDM device, eliminating variable data across multiple machines.

2.Most testing methods for ANSI/ISEA 105-2016 will remain the same except reducing the distance the testing blade travels from 25mm to 20mm.

3.The EN standard will use the Coup testing device, unless certain dulling materials cannot be cut in 60 cycles. In such cases, method EN ISO 13997 will be used with the TDM device, which is the same as the new ANSI/ISEA standard.

Comparison:

It has been observed that the ANSI level 5 materials are more rigid than the level 5 materials of EN 388. The difference is not huge but if we talk about comparison, ANSI rated rating excels.

Which test method is better?

Prior to the incorporation of ISO 13997, the ANSI/ISEA 105 standard was preferred in the industry because of its accuracy. However, now that the EN 388 standard uses the TDM-100 for part of its testing, it’s not so black and white.

ANSI could still be considered the superior standard because of its simplicity and reducing the risk of making an error during the testing process because:

· The blade is changed after each test to prevent dulling

· It’s straightforward – there’s no comparing the material to a test cloth

· It’s suitable for all types of gloves

ANSI/ISEA and EN388 cut levels are NOT

Regardless of the test you are using, it’s important to remember that these tests are not equivalent. A glove that withstood 3059 grams of cut force on the Coup Test (CE cut level 5) will not automatically be an ANSI level A6. The glove must be tested using a TDM-100 to

Which products should I choose with new

After the new standard of EN388 & ANSI released,you can clearly differentiate the level.Products of different level could be uesd for different purposes,you can choose them base on your industry,environment or other factors.

EN

EN  ES

ES PT

PT AR

AR DE

DE IT

IT FR

FR RU

RU JA

JA